|

|

|

|

Creative Designs,

manufacturer and an

exporter of high quality

leather goods, was

started in the year

1984. We bring to

leather goods

manufacturing with many years

of rich and varied

experience and

understanding of

customers’ requirements

developed over the years

by working with our

highly discerning and

quality conscious

overseas customers. The

relevant technical

background of the

company's director in

the field of leather,

keeps the organization

geared to offer the

customers a wide range

of leather products. The

company has a well

equipped factory with

all the in-house modern

facility.

Almost from the inception of the company we have been exporting our high

quality leather products

to diverse overseas

markets. We manufacture

strictly according to

the specifications of

the overseas buyers

and we

guarantee high

quality and

prompt delivery.

We are |

|

|

|

always on the move to meet

international fashion trends and we

offer new collections to our

customers on a regular interval. |

|

|

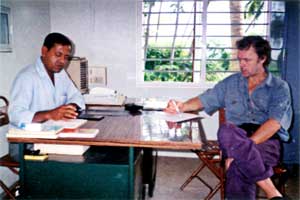

Attending

customers

from Europe |

|

|

Leather :

As for the leather we use, we are

aware of the environmental issues

and as a responsible corporate

citizen, we have arranged for

testing the leather with outside

autonomous bodies to ensure that

banned chemicals are not used.

However, our special focus is on

VEGETABLE TANNED leather adopting an

Eco-friendly tanning process. It

reflects a care for the craftsman

and the environment, using processes

which have long since disappeared

from the modem leather industry. The

tanning is done with vegetable

extracts collected from the barks

and seeds of Indian and East African

forests, soaking the hides in pits.

This is the only form of tanning

which is not detrimental to the

environment.

Our leather is full grain

cowhide, vegetable tanned and hand

dyed. Vegetable tanning takes 40

days whereas chrome tanning takes

one week. The tanning is done in

pits and wooden drums. When the

vegetable extracts have been fully

absorbed, then the vegetable oils

are applied to make the hide supple.

Each hide is hand-rubbed with

aniline dyes, leaving the grain

visible, enhancing the strength and

beauty gained from the vegetable

tanning process and giving our

products a strong natural look. We

take special care to avoid excessive

use of pigments and binders that

make the leather look like synthetic

material. We do not use any chemical

which is harmful. Labor used is

strictly adult. We also supply bags

in other types and finish of

leather.

|

|

|

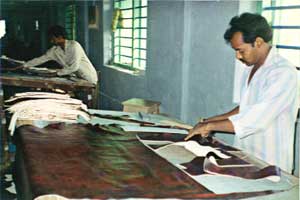

Cutting

(left)

Skiving

(right) |

|

|

|

|

Production :

Our leather bags are made of

carefully selected top grain

cow-calf and cow hides. Our bags are

all handcrafted from the stage of

cutting to finishing. Every stitch,

zipper, buckle and design component

exemplify the quality built into

each piece that makes up our

collection. Our bags are designed

with classic well-balanced

proportions and will last a lifetime

with minimal care. Each of our

leather products embodies the

perfect balance between aesthetics

and functionality. Sizes, shapes,

pockets and straps are carefully

considered to provide maximum

efficiency, comfort and convenience.

We select only the finest leathers

for their tactile quality, strength,

character and grain. Like

fingerprints, no two grain patterns

are exactly alike. Our method of

slow curing brings the natural

markings to the top, which makes

every Briefcase and bag original as

well as unique. All the briefcases

have a detachable strap. They are of

three gusseted depending on the

design. They have provision for

business cards, pens, calculator and

mobile phone etc. They have two to

three inside compartments, with a

center zip compartment, an inside

back wall zip pocket and a full

length outside back zip pocket. All

important stress points are double

stitched tied reinforced with brass

rivets. We provide four metal brass

feet’s below the gussets so that the

bags do not fall but stand well. Our

bags do not fall apart as all the

gussets are first stitched, then

covered with leather binding then

stitched a second time.

|

|

|

Production

(left)

Bag making

& Assembling

(right) |

|

|

|

|

Accessories

: The various components like

the locks, zippers, magnetic

buttons, snap buttons, rivets are

all imported from different parts of

the world. The locks are Swiss make

Amiet locks, the Mat finished locks

are imported from Hong Kong, the

zippers are imported from Taiwan,

magnetic buttons from Italy, snap

buttons from Japan. The buckles and

fittings are in solid brass,

unbreakable with natural luster,

each sandcasted and polished by hand

individually. The locks and fittings

can be given in brass or mat nickel

finish.

|

|

|

Stitching

(left)

Cleaning

& Finishing

(right) |

|

|

|

|

Quality Assurance : Quality

has been the emphasis in every

endeavor of ours. Customer

satisfaction is extremely important

for us. References if required from

our customers regarding the quality

of our products and our reputation

can be made available on request.

|

|

Our Goal :

Our goal is to instill a deep sense

of discipline, quality consciousness

and achieve a high degree of

productivity among our skilled

workforce and satisfy our valued

customers.

|

|

Motto

: We are driven by our

commitment to quality and product

innovation. Our motto is to strive

for perfection and we take work as

our yoga. Our mission is to maintain

the highest standard of ethical

conduct in all our business

activities.

|

|

Countries Exported :

Australia, U.K.,

Holland, Germany, Canada, U.S.A., France,

Austria. |

|

|

|

|

|

|

©

COPYRIGHT CREATIVE DESIGNS, 2006-2010 |

|

|